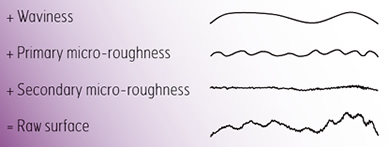

Limiting the material removal to specific frequency ranges gives MMP® Technology other benefits that differentiate it from classic polishing processes. Since the frequencies of roughness MMP Technology removes are significantly higher than the frequencies of the underlying form of the part, the resulting mirror-like finish leaves edges sharp and fine details undisturbed, meaning that MMP Technology is very well suited to creating uniform mirror-like finishes on complex geometries.

However, since MMP Technology is an isotropic (homogeneous) treatment, if obtaining a mirror-like surface requires removal of form errors (i.e. low frequency), MMP Technology may not be a good solution. Defects in the form of the part will require localized removal of material, and probably a lot of material relative to the amounts MMP Technology typically removes. In general, if a part requires non-homogeneous removal of material (i.e. changes to the actual shape of the part), MMP Technology is not likely to be the best choice.